Urban development demands ever-increasing output and precision in kerbstone cutting. Haineng provides advanced end-to-end equipment solutions for kerbstone production. This curb stone machine line processes diverse materials including granite, marble, limestone, basalt, sandstone, concrete, and engineered stone to manufacture kerbstones, paving blocks, guardrails, and square semi-finished products. Haineng kerbstone cutting machine production line can process a wide range of common stones, such as granite, marble, sandstone, basalt, limestone and quartzite, as well as concrete, cement and lightweight building materials, including artificial stone blocks.

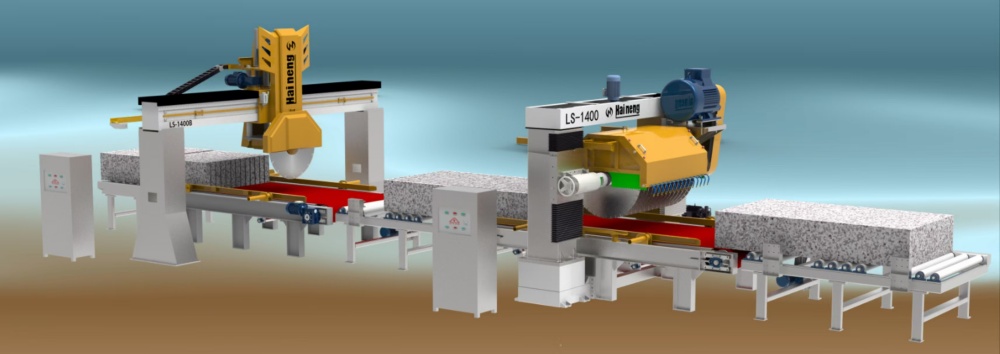

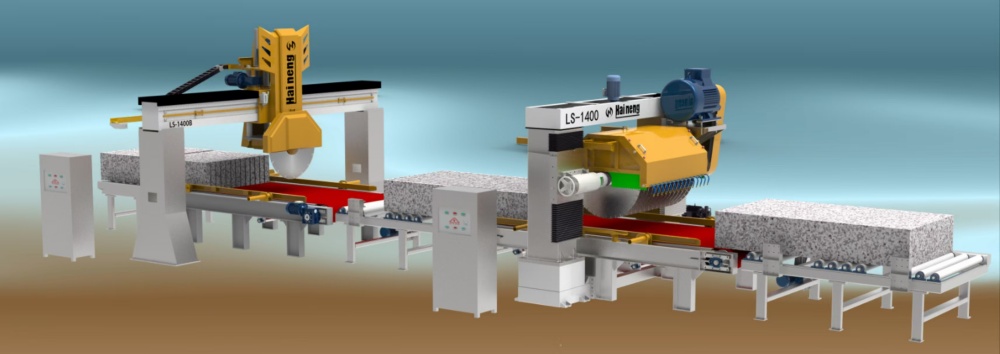

Highly Efficient Automated Kerbstone Cutting Production Solution

Kerbstone cutting machine production line features longitudinal (fixed-width) automatic feeding, longitudinal (fixed-width) automatic cutting, transverse (fixed-length) automatic feeding, transverse (fixed-length) automatic cutting, and automatic discharge to subsequent processes. Follow-up stages can incorporate optional equipment for chamfering, surface roughening, and other treatments, ensuring fully intelligent operation throughout.

Advantages:

1. Mainframe employs an integral welded structure for stable, durable cutting

2. Hydraulic system ensures smooth lifting and precise cutting

3. Dual-carriage independent cutting minimises loading/unloading time for maximum efficiency

4. Fully welded chassis undergoes machine-planned machining to guarantee parallel side rails

5. Customisable cutting widths and saw blade diameters

6. No concrete foundation required; simple electrical controls for user-friendly operation

Feature:

High output: Equipment can simultaneously mount 10 to 14 x 1200mm diameter saw blades for operation, significantly boosting production.

High productivity: Stone is conveyed via rollers between two units, eliminating manual loading/unloading time and enhancing efficiency.

High cutting standards: Utilises PLC programmable control systems and hydraulic lifting mechanisms, equipped with templates and hydraulic arms. Employs shallow, rapid-movement cutting techniques to ensure precision and quality.

Low Capital Investment: Compared to other models on the market with equivalent capacity, equipment investment can be reduced by 20% to 30%, alleviating pressure on corporate capital expenditure.

Low Consumable Costs: The shallow and rapid cutting method reduces the number of cuts required and accelerates cutting speed, effectively lowering diamond blade wear by 30% to 50%.